Fitting a Hull Anode

Fitting a Hull Anode on a boat

Select a position on the hull that is under the waterline and preferably within the bilge of the boat.

It needs to be easily accessible inside the boat so that the bolts can be tightened and connections attached and maintained.

The position should be aft of any depth or log transducers and “within sight” of what is being protected and with the shortest possible cable runs.

Drill the appropriate holes which need to be be slightly oversize, 1-2mm bigger, and coat the inside of the hole with paint or epoxy to seal them. This is important with wood, ferrocement, steel and some GRP hulls with a core. With my ferro boat I drilled a few millimetres bigger, filled the hole up with epoxy filler and then drilled through in the centre to give an insulated sleeve.

Fabricate a backing pad for the inside of the boat using timber or marine ply which can be painted or epoxied to increase it's life.

Test fit the bolts and mark the inside to indicate the thickness of hull and backing pad.

Wrap the part of the bolt that touches the hull in heat shrink wrap, alternatively I use few turns of electrical insulation tape.

Wrap the remaining thread in a little masking tape.

Find a friend to help before you start the next bit.

Read the sealant instructions.

Put your gloves on.

Coat the hole and end of the bolt in marine grade sealant.

Push the bolt through from the outside, remove the masking tape and tighten from the inside while holding the outside using a couple of nuts locked together. Generally not too tight as they can be nipped up when the sealant is dry.

When dried and tightened connect the wires internally using the bolts then smear with grease or Vaseline to prevent corrosion.

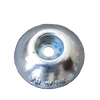

Fit the anode to the hull with a backing pad behind, using the serrated washers and nuts and again coat in grease or ideally lanolin which I find is far superior.

You may have to hold the inside to stop the bolt turning while tightening up the nuts on the outside.

Use a multimeter on the outside of the boat to ensure you are connected between where you want to and check it every year.

Do not paint the anode with antifouling.

Use good marine multi strand copper wire on the inside, smearing any connections in grease or vaseline. I use jubilee clips around my seacocks with the wire trapped underneath to give the best connection.